How to Safely Work with High Voltage Systems

Working with high voltage systems is not something to approach lightly. Whether you’re a professional electrician, an industrial technician, or a DIY enthusiast with the right training, the risks are very real. High voltage electricity can be invisible, silent, and unforgiving. One small mistake could result in severe injury or even death.

You’ve likely felt the hum of a transformer, noticed the sparks from a poorly insulated wire, or simply admired the power that flows through our homes, factories, and grids every day. That awe comes with responsibility. Every time you step near high voltage equipment, you’re entering a zone where respect, knowledge, and proper precautions are your best tools.

In this article, you’ll discover everything you need to know about how to safely work with high voltage systems—from understanding the dangers and legal requirements to selecting the right personal protective equipment (PPE), performing maintenance, and avoiding common mistakes. By the end, you’ll have actionable strategies that ensure your safety and the safety of everyone around you.

Table of Contents

Understanding High Voltage Systems

Before you touch a single wire, it’s crucial to understand what high voltage systems are and why they demand such caution.

What is Considered High Voltage?

High voltage typically refers to electrical systems operating at:

- Above 1,000 volts AC

- Above 1,500 volts DC

Examples include:

- Transmission lines that carry electricity across cities or states

- Industrial machinery and equipment

- Electrical substations

Working near these systems requires specialized knowledge, training, and tools. Even small equipment failures or mistakes can trigger life-threatening accidents.

Why High Voltage Systems are Dangerous

The hazards of high voltage electricity are numerous:

- Electric Shock: Contact with live circuits can stop your heart or cause severe burns.

- Arc Flash & Arc Blast: A sudden release of energy can produce heat over 35,000°F, causing devastating injuries.

- Fire Hazards: High voltage faults can ignite nearby flammable materials.

- Equipment Damage: Even if you aren’t hurt, improperly handled systems can destroy expensive equipment.

According to OSHA reports, thousands of electrical incidents occur yearly in workplaces, many of which could be prevented with proper safety measures.

Essential Safety Standards and Regulations

Before performing any work, familiarize yourself with the rules that govern high voltage work. Compliance is not optional; it’s the foundation of safety.

Global & National Guidelines

- OSHA (U.S.): Sets occupational safety standards and enforces compliance.

- NFPA 70E (Electrical Safety in the Workplace): Focuses on protecting workers from electrical hazards.

- IEC & IEEE: Provide international standards for electrical installations, equipment, and safety protocols.

Legal Requirements You Must Follow

- Training Certifications: Only qualified personnel should work on high voltage systems.

- Lockout/Tagout (LOTO): Legally required procedures for safely de-energizing equipment.

- Personal Protective Equipment (PPE): Mandatory standards exist for gloves, clothing, tools, and footwear.

Ignoring these regulations not only endangers lives but can lead to legal penalties and severe financial consequences.

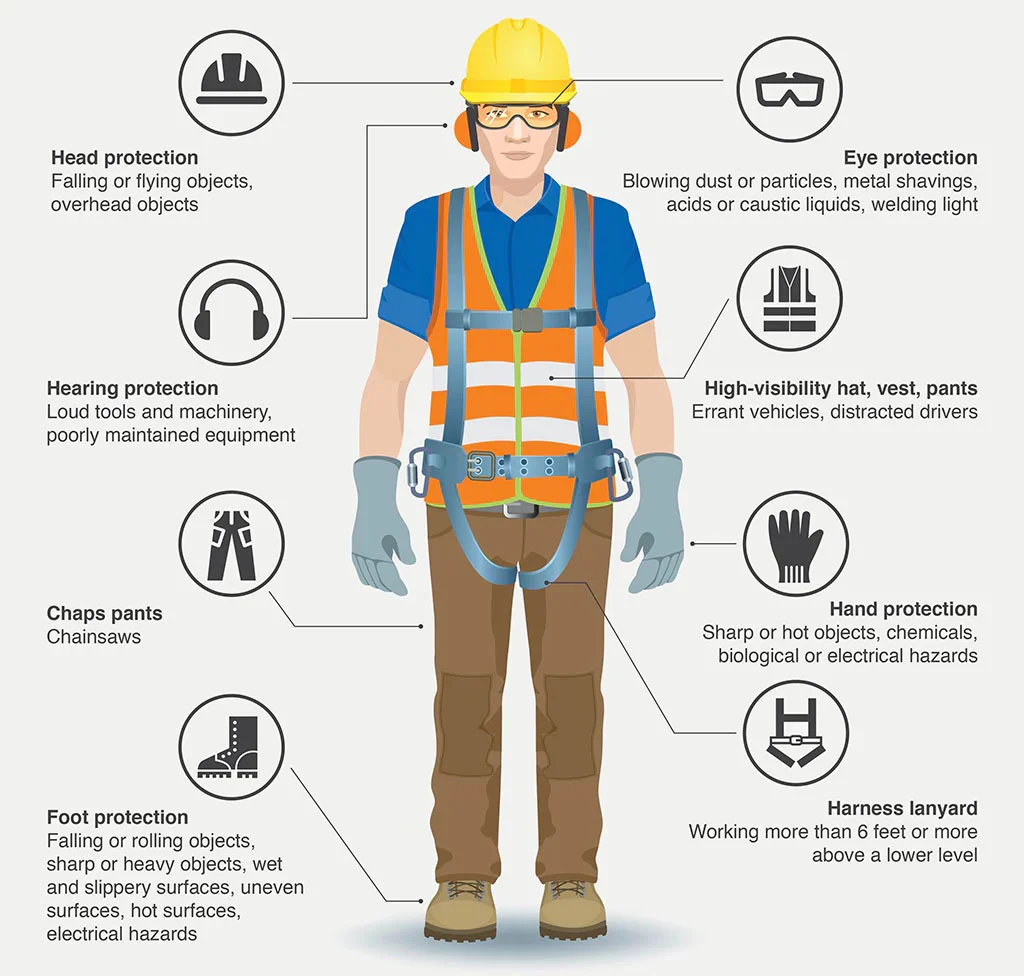

Personal Protective Equipment (PPE) for High Voltage Work

One of the most critical components of safety is wearing and using the correct PPE. Your life literally depends on it.

PPE Checklist

| PPE Item | Purpose | Example Rating/Standard |

|---|---|---|

| Insulated Gloves | Protects hands from electrical shock | ASTM D120, Class 2+ |

| Arc-Rated Clothing | Shields from arc flash burns | NFPA 70E compliant |

| Insulated Tools | Prevents electrical current flow | IEC 60900 certified |

| Face Shield & Goggles | Protects eyes from arcs and sparks | ANSI Z87.1 |

| Safety Footwear | Prevents grounding path through your body | ASTM F2413 |

How to Inspect PPE Before Use

- Check for tears, cracks, or worn spots in gloves or clothing.

- Confirm certification marks are valid.

- Ensure tools are insulated and free from damage.

- Inspect footwear for proper insulation and fit.

Step-by-Step Guide: How to Work Safely with High Voltage Systems

Proper preparation, execution, and post-job review are essential to prevent accidents.

Preparation Phase

- Risk Assessment & Job Planning

- Evaluate the worksite for hazards.

- Determine the tools, PPE, and personnel needed.

- Lockout/Tagout (LOTO) Procedures

- De-energize the system.

- Attach lockout devices and tags.

- Confirm Power Isolation

- Use voltage testers to ensure circuits are truly de-energized.

During Work

- Use only insulated tools.

- Maintain safe clearance distances from live circuits.

- Never work alone; always employ a buddy system.

- Continuously test voltage to prevent accidental energization.

After the Job

- Properly re-ground any temporary connections.

- Inspect the system for integrity before re-energizing.

- Document all actions taken for legal and safety records.

Common Mistakes When Working with High Voltage Systems

Even experienced professionals can make errors. Avoid these pitfalls:

- Skipping PPE because “it’s a quick job.”

- Assuming equipment is de-energized without testing.

- Using damaged tools or frayed cables.

- Working alone in high-risk areas.

Preventive Maintenance and Long-Term Safety

Proper maintenance can prevent accidents and extend equipment life.

Why Maintenance Reduces Risk

- Identifies early signs of failure.

- Reduces chances of shock, arc flash, or fires.

- Keeps tools and machinery performing optimally.

Maintenance Checklist

- Regular insulation resistance testing.

- Thermal imaging for hot spots.

- Cleaning and tightening all connections.

- Replacing worn or damaged components.

Real-Life Case Studies and Lessons Learned

Learning from real incidents can save lives:

- Industrial Arc Flash Incident: A technician bypassed a lockout procedure, causing burns and equipment damage. Lesson: Never skip LOTO.

- Home DIY Shock: A homeowner attempted to fix a live panel without gloves. Lesson: Always use proper PPE.

- Maintenance Oversight: A transformer failed due to neglected inspections. Lesson: Schedule preventive maintenance diligently.

Frequently Asked Questions (FAQ)

What is the safest way to work with high voltage systems?

Always de-energize the system, wear certified PPE, and follow OSHA/NFPA safety guidelines.

What PPE is mandatory when working with high voltage systems?

Insulated gloves, arc-rated clothing, insulated tools, face shields, and protective footwear.

Can you work alone on high voltage systems?

No. Always have a buddy system to respond in emergencies.

How often should high voltage equipment be maintained?

Annually at minimum, with additional inspections based on usage and environmental conditions.

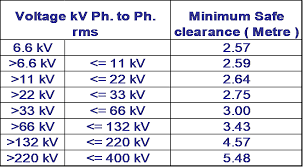

What distance should you maintain from live high voltage equipment?

Follow OSHA clearance tables according to the voltage level; maintaining proper distance prevents arcs and accidental contact.

Conclusion: Respect the Power, Protect Your Life

Electricity powers our homes, businesses, and industries, but it demands respect. Every time you work with high voltage systems, your safety isn’t just about compliance—it’s about life.

Following proper procedures, wearing PPE, performing preventive maintenance, and avoiding common mistakes will keep you and your team safe. Remember, working with high voltage systems is a privilege and a responsibility.

Call-to-Action: Share this guide with colleagues, train your team regularly, and make safety your top priority. Equip yourself with knowledge, tools, and discipline—the results are not just safety, but peace of mind.